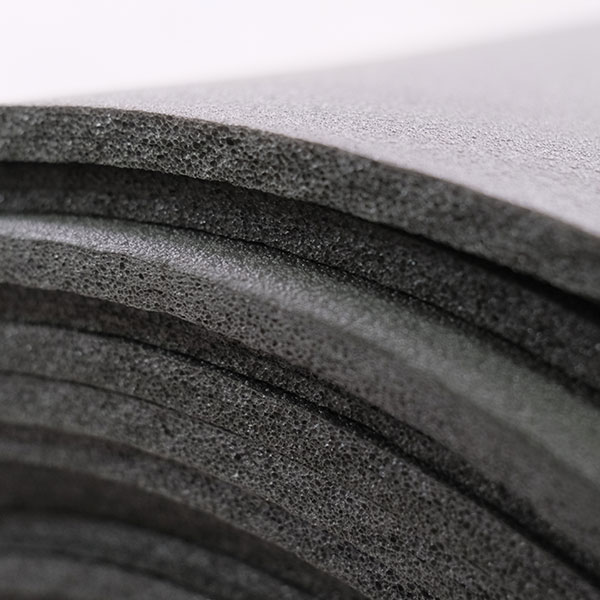

Neolon™️ XPE Foam Features

- Thermal insulation

- Fire Retardant

- Superior Buoyancy

- Non Toxic

- Resistance to Chemical Solvents

- Noise and Vibration Reduction

- Resilient and Long Lasting

For Marine Buoyancy Foam Applications:

Buoyancy foam can be either basic buoyancy foam, which allows the vessel to stay afloat with a certain weight on board, or level buoyancy foam, which keeps the vessel floating level and prevents it from capsizing in calm water.

This foam complies with standards for resistance to hydrostatic pressure, stability under temperature cycling, resistance to water absorption, and resistance to hydrocarbons and bilge cleaner.

For Construction Applications:

A high-quality foam tested by UNSW to last more than twice as long as other foams. Can be cut to shape or size for roof infills, bridge joints, expansion joints, concreting foam, backing rod, just about any foam construction application, PJ Bower’s Neolon has you covered!

For Insulation Applications:

Strong resistance to moisture, chemicals, cold weather and high temperature.

Sound Insulation – Results vary depending on frequency of the sound. Low Frequencies and high frequencies are reduced by up to 30Db. Mid frequencies are reduced by up to 15Db.

Temperature Insulation – a foil faced foam should be used see Neolon XPE Full Roll or Neolon Foam Tube for foiled foam options.