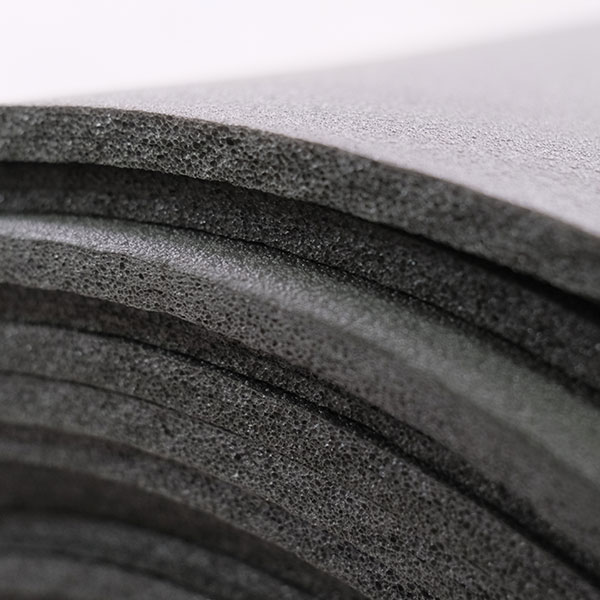

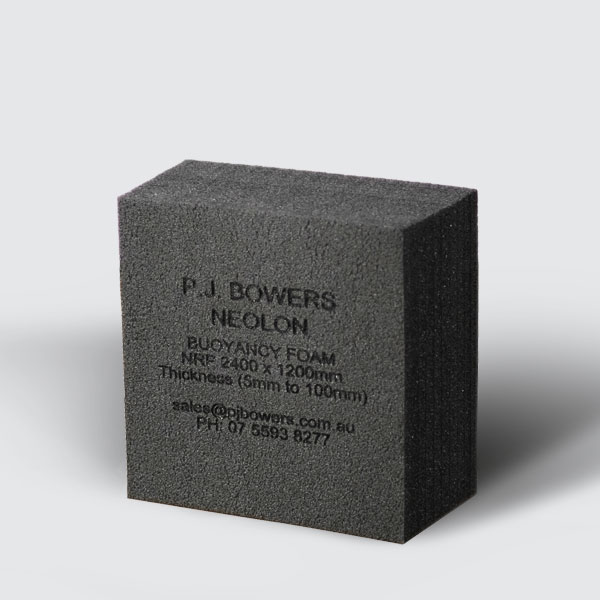

One of our speciality foams, for many applications such as marine, insulation, packaging and construction. With many properties such as flame retardant, fuel resistant and UV resistant.

Certifications:

Fire Retardancy: ASTM 1530.3, BS EN ISO 4589 3:2017

Construction Certification: MRTS77, RTA 3204

Marine Certification: NATA 14722

Sheet sizes are:

2400 x 1200mm (2.4 x 1.2m)

To calculate how many sheets are required:

To cover an area (m2)

To cut many rectangles or squares

To fill a space (m3)

To float a maximum weight above water (Kg)

For Marine Applications:

• Does NOT absorb water.

• It is resistant to cleaners, oils, high-octane petrol, diesel or kerosene

• You can bend it or cut it to fill any space

• Doesn’t wear away from abrasion

• Can be removed at anytime or if the hull needs to be repaired

Learn More

Cleaning Your Foam

Domestic Commercial Vessel Instructions

Density – refers to the mass per unit volume of foam material. Higher density foam is firmer, lower density foam is softer.

StickyBack – a peel-off adhesive tape, for an easy stick-on foam solution.