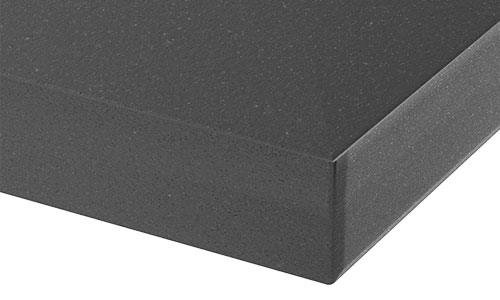

closed cell foam for sale.

Made to Order. Cut to Size.

We have the closed cell foam stock options, flexibility and refined machine capabilities to fulfill your order without back-orders or delay.

Pick ups: please wait for your order to be ready before pickup, we make to order.

Our corporate website is available at: pjbowers.com.au

Apply for Trade Pricing and Save

Apply with your ABN and receive trade pricing.

Login to see your pricing.

Made to order

1-3 days

Your choice of freight carrier or pickup

Secure checkout with Stripe

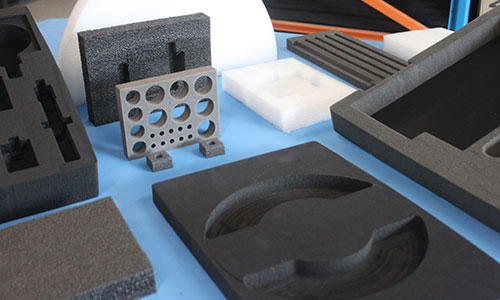

3D design service for CNC

Learn More

Tool boxes and cases designed and manufactured for Australia’s most precision based industries.

Packaging designs to suit any item. Offer a premium packaging solution and protect valuable assets.

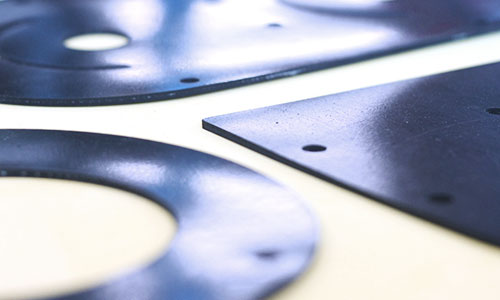

Industrial precision gaskets for all industries, whether, manufacturing, reconditioning or a repair.

Understand how the hardness of foam is measured, and the expected hardness across different densities of EVA and PE foams.

How to clean foam? Closed cell foam is waterproof and chemical resistant, making wash up a breeze.

Packaging designs to suit any item. Offer a premium packaging solution and protect valuable assets.

Needing foam for your business?

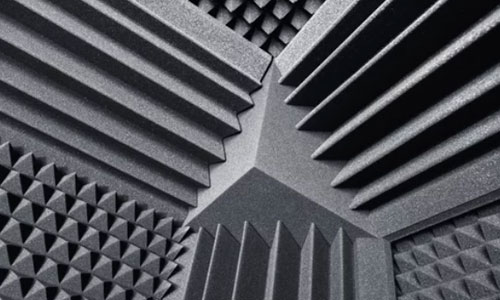

Selected foams and designs to ensure parts are organised, safe and secure – packaging of expensive and sensitive materials.

closed cell foam Comparison

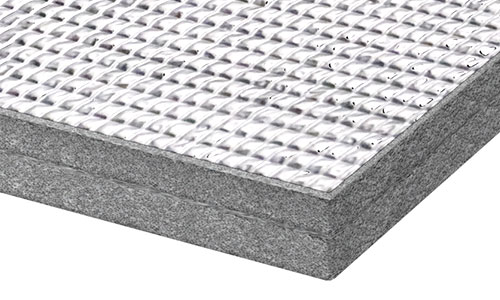

Applications such as marine, packing and construction. With many properties such as flame retardant, fuel and UV resistance.

Applications such as marine, packing and construction. With many properties such as flame retardant, fuel and UV resistance.

Widely used in construction to allow expansion of the concrete. 3M peel-off, Sticky back is applied for ease of installation.

Used in bridge construction as expansion joint filler, facilitating the installation of filler joints and reducing labour times.

Many Diametres available, with or without thermal insulation. Used for external pipe insulation, air conditioning and automotive plumbing.

Frequently Asked Questions about closed cell foam

Because we have refined machine knowledge and a range of unique capabilities, this means we custom make to your order, usually the next day!

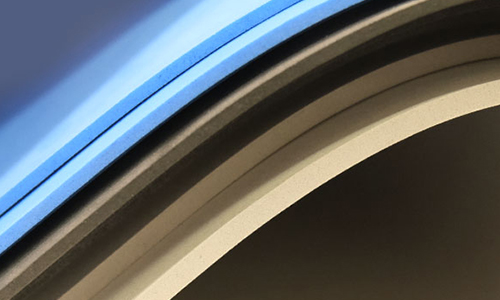

Closed-cell foam is a lightweight material composed of sealed, air-tight, water-tight cells. These cells are densely packed, forming a structure impermeable to air and water. Due to its closed nature, this foam boasts excellent insulation and resistance to moisture.

Key Characteristics:

Lightweight

Buoyant

Excellent Insulation

Moisture Resistance

Common Applications:

Closed-cell foam finds versatile use in insulation for buildings, flotation devices like life jackets, and various padding applications such as camping mats and protective gear.

Explore the benefits of closed-cell foam for your specific needs, combining lightweight durability with effective insulation and water resistance.

For sheet or roll orders you can expect a working day or two until dispatch. Depending on your location you will have multiple freight options on checkout. From express to more affordable options.

The freight options presented on checkout are supplied by a third-party freight broker – this is to give our customers a variety of options to suit their needs.

Rest assured, these are the same fright options and prices we offer our customers offline.

Yes, we can usually offer samples on request.

However, please see our specification sheets to understand thicknesses, densities, compression, material characteristics etc, as the sample pack will not include all possible options.

Our foam sheets come in two standard sizes: 1.2 x 2.4 meters or 1 x 2 meters, depending on the type of foam. This results in square meterages of either 2.88m² or 2m².

To help you calculate the number of sheets needed for a specific area, consider this example: for a 36m² area, you would require either 12.5 sheets (36 divided by 2.88) or 18 sheets (36 divided by 2) to cover the entire space

Yes, depending on your intended use for the foam.

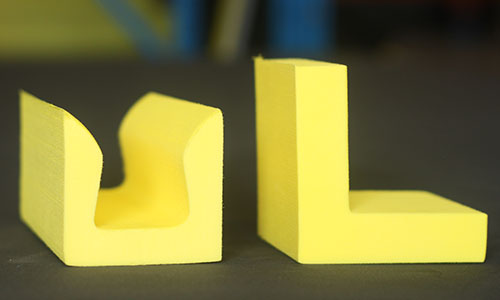

Check our foam comparisons and spec sheets to understand what foams are easiest to cut, and what methods may be required to make that cut.

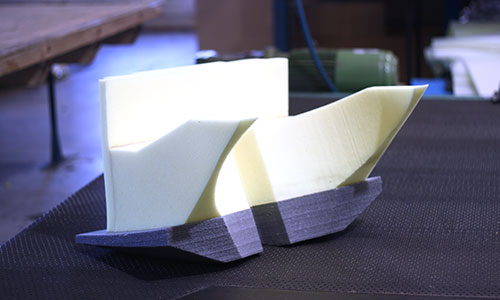

Note: Cut or 3D design examples shown on our website are professional CNC cuts.

Foam is light and it’s cellular structure is superior for bonding which makes a great bonding surfaces for glues and is an easily sculpted material if the correct type and density is used.

Foam is great for prototypes and parts that need to be sculpted but also have foam properties like flex, compression, bounce, cushioning, impact resistance etc.

Neolon XPE, PE and EVA are all resistant to chemicals such as fuels, oils and cleaners. Spec sheets should be requested for other chemicals.

See our tech specs for foams that are designed for specific applications where chemical exposures are considered and tested for chemical resistance.

Yes but it will require industry machinery and professional knowhow, please contact us for custom orders.

Laminating or ‘welding’ foam is a strong solution to altering the width, length or thickness of foam. The join is often stronger than the material itself.

Our specification sheets can inform you of the strengths and weaknesses of each foam type when exposed to different elements such as heat, chemicals, water, compression, tear etc.