How to install foam

These methods can be adapted based on the specific requirements of the project, the properties of the foam material, and the desired outcome.

It’s essential to consider factors such as the environment, load-bearing requirements, and longevity when choosing the appropriate method for installing or mounting foam materials.

Contact Adhesive

Tips: Apply adhesive to both surfaces, Wait up to an hour to become tacky, then the contact of both surfaces will begin on contact.

Advantages: A strong permanent bond. We joining foam-to-foam the join will be stronger than the foam itself.

Disadvantages: Is a permanent adhesion, removal of the foam will very likely result in damage to the foam and/or the other bonding surface.

Pressure Sensitive Adhesive Or Tape

Tips: Pressure sensitive is usually only a temporary hold, however it can stick on dirty and uneven surfaces.

Suitable for: expansion joints, tacky repositionable pieces, test fitting/positioning while installing a permanent fixing.

Advantages: In some applications is strong enough to provide a good bond but can be removed or adjusted with minimal damage to the bonding surface. Or can be permanently fixed using another method.

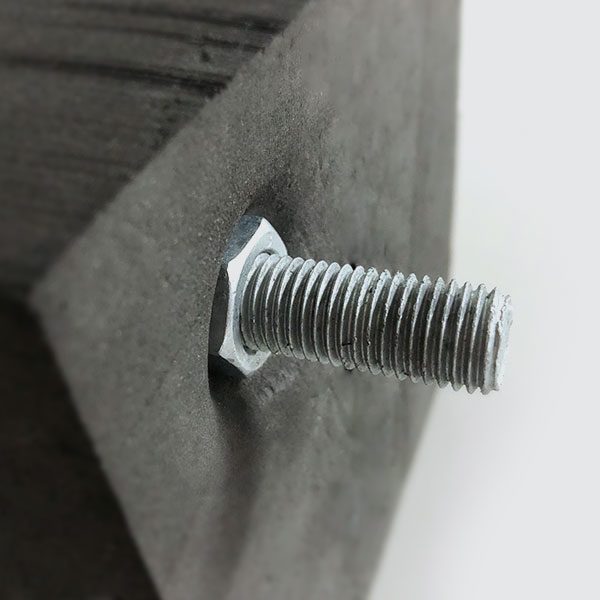

Mechanical Fastening (Screws, Bolts, Nuts)

Tips: Large surface washers will spread the load across the foam allowing for more torque on the bolt or screw without tearing or puncturing the foam more than the diameter of the bolt or screw.

Suitable for: heavy-duty, higher load, higher impact applications, removable, semi-destructive applications.

Advantages: Easy to control the cut and steer the blade along non-uniform paths.

Disadvantages: Can be difficult to keep the saw true and is a slower cutting process.

Liquid Nails

Suitable for: Strong permanent adhesion that is difficult to remove. Works best if spread evenly on the applied surface.

Advantages: Good adhesion to unconventional surfaces like metals, woods, concretes etc.

Disadvantages: Can be messy to apply and evenly distribute across the surface.

Sealing With Silicone, Caulk, Fillers

Suitable for: Compression fit Neolon foams that are being used as gap fillers, tubes, backing rod, expansion joints etc.

Advantages: Limits the amount of liquid filler required, is less prone to failure from joint movement over time. Better adhesion to foam than solid surfaces.

Disadvantages: Can only be used for sealing or filing, not adhesion.