DIY Cutting Your Foam

We have compared many cutting methods, the results, advantages, disadvantages and tips.

Understanding the possibilities of your foam will help complete your next project.

*The DIY cutting methods are only used as a guide, not as an guaranteed result.

As there is many material, tooling and user variables.

Edge guides, templates, measurements and test cuts are recommended for best results.

Professionally Converted by PJ Bowers

Tips: Consider sheet yield, quantity and a one-off drawing fee when requesting a quote.

Suitable for: Best of foam tolerances and production of many pieces and custom designs.

Advantages: large scale, high quantity production with CNC machine precision, any shape variable depth routing etc can be easily achieved.

DIY cutting comparison

*Image from left to right:

1. Serrated bread knife cut

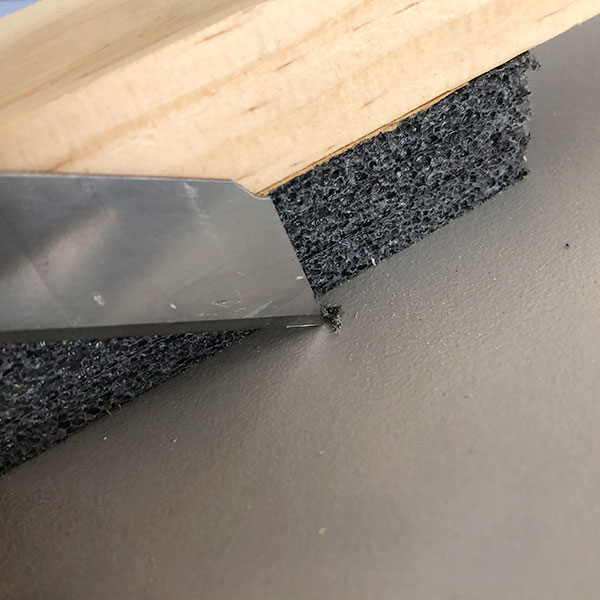

2. Stanley box knife cut

3. Circular saw cut

4. Hand held router and circular saw

Box Cutter

Even with guides, templates, fences etc the blade’s angle can become more inconsistent as the cut becomes deeper.

Hand Router

Bandsaw, Table Saw, Circular Saw With High Tooth Count